Titanic

:Passengers of Titanic

:Passengers of Titanic

Dimensions and Layout - -Features- - Building and Preparing the Ship

RMS Titanic was a British passenger liner, operated by the White Star Line, that sank in the North Atlantic Ocean on 15 April 1912 after striking an iceberg during her maiden voyage from Southampton, England, to New York City, United States. Of the estimated 2,224 passengers and crew aboard, more than 1,500 died, making it the deadliest sinking of a single ship up to that time.[a] It remains the deadliest peacetime sinking of an ocean liner or cruise ship.[4] The disaster drew public attention, spurred major changes in maritime safety regulations, and inspired many artistic works.

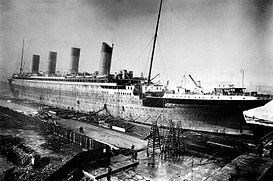

RMS Titanic was a British passenger liner, operated by the White Star Line, that sank in the North Atlantic Ocean on 15 April 1912 after striking an iceberg during her maiden voyage from Southampton, England, to New York City, United States. Of the estimated 2,224 passengers and crew aboard, more than 1,500 died, making it the deadliest sinking of a single ship up to that time.[a] It remains the deadliest peacetime sinking of an ocean liner or cruise ship.[4] The disaster drew public attention, spurred major changes in maritime safety regulations, and inspired many artistic works.RMS Titanic was the largest ship afloat at the time she entered service and the second of three Olympic-class ocean liners built for the White Star Line. She was built by the Harland and Wolff shipyard in Belfast. Thomas Andrews, the chief naval architect of the shipyard, died in the disaster. Titanic was under the command of Captain Edward Smith, who went down with the ship. The ocean liner carried some of the wealthiest people in the world, as well as hundreds of emigrants from the British Isles, Scandinavia, and elsewhere throughout Europe, who were seeking a new life in the United States and Canada.

The first-class accommodation was designed to be the pinnacle of comfort and luxury, with a gymnasium, swimming pool, smoking rooms, high-class restaurants and cafes, a Turkish bath, and hundreds of opulent cabins. A high-powered radiotelegraph transmitter was available for sending passenger "marconigrams" and for the ship's operational use. Titanic had advanced safety features, such as watertight compartments and remotely activated watertight doors, contributing to its reputation as "unsinkable".

Titanic was equipped with 16 lifeboat davits, each capable of lowering three lifeboats, for a total of 48 boats. However, she actually carried only 20 lifeboats, four of which were collapsible and proved hard to launch while she was sinking (Collapsible A nearly swamped and was filled with a foot of water until rescue; Collapsible B completely overturned while launching). Together, the 20 lifeboats could hold 1,178 people—about half the number of passengers on board, and one-third of the number of passengers the ship could have carried at full capacity (a number consistent with the maritime safety regulations of the era). When the ship sank, the lifeboats that had been lowered were only filled up to an average of 60%.

Dimensions and layout

Titanic was 882 feet 9 inches (269.06 m) long with a maximum breadth of 92 feet 6 inches (28.19 m).Her total height, measured from the base of the keel to the top of the bridge, was 104 feet (32 m).[16] She measured 46,329 GRT and 21,831 NRT[17] and with a draught of 34 feet 7 inches (10.54 m), she displaced 52,310 tons.[5] All three of the Olympic-class ships had ten decks (excluding the top of the officers' quarters), eight of which were for passenger use.

Features

Titanic propulsion was supplied by three main engines—two reciprocating four-cylinder, triple-expansion steam engines and one centrally placed low-pressure Parsons turbine—each driving a propeller. The two reciprocating engines had a combined output of 30,000 horsepower (22,000 kW). The output of the steam turbine was 16,000 horsepower (12,000 kW).[16] The White Star Line had used the same combination of engines on an earlier liner, Laurentic, where it had been a great success.[29] It provided a good combination of performance and speed; reciprocating engines by themselves were not powerful enough to propel an Olympic-class liner at the desired speeds, while turbines were sufficiently powerful but caused uncomfortable vibrations, a problem that affected the all-turbine Cunard liners Lusitania and Mauretania.[30] By combining reciprocating engines with a turbine, fuel usage could be reduced and motive power increased, while using the same amount of steam.[31]The two reciprocating engines were each 63 feet (19 m) long and weighed 720 tons, with their bedplates contributing a further 195 tons.[30] They were powered by steam produced in 29 boilers, 24 of which were double-ended and five single-ended, which contained a total of 159 furnaces.[32] The boilers were 15 feet 9 inches (4.80 m) in diameter and 20 feet (6.1 m) long, each weighing 91.5 tons and capable of holding 48.5 tons of water.[33]

They were fuelled by burning coal, 6,611 tons of which could be carried in Titanic's bunkers, with a further 1,092 tons in Hold 3. The furnaces required over 600 tons of coal a day to be shovelled into them by hand, requiring the services of 176 firemen working around the clock.[34] 100 tons of ash a day had to be disposed of by ejecting it into the sea.[35] The work was relentless, dirty and dangerous, and although firemen were paid relatively well,[34] there was a high suicide rate among those who worked in that capacity.

Building and preparing the ship

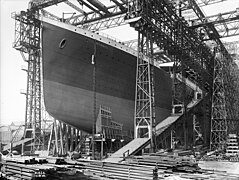

The sheer size of the Olympic class vessels posed a major engineering challenge for Harland and Wolff; no shipbuilder had ever before attempted to construct vessels this size.[76] The ships were constructed on Queen's Island, now known as the Titanic Quarter, in Belfast Harbour. Harland and Wolff had to demolish three existing slipways and build two new ones, the largest ever constructed up to that time, to accommodate both ships.[10] Their construction was facilitated by an enormous gantry built by Sir William Arrol & Co., a Scottish firm responsible for the building of the Forth Bridge and London's Tower Bridge. The Arrol Gantry stood 228 feet (69 m) high, was 270 feet (82 m) wide and 840 feet (260 m) long, and weighed more than 6,000 tons. It accommodated a number of mobile cranes. A separate floating crane, capable of lifting 200 tons, was brought in from Germany.[77] The construction of Olympic and Titanic took place virtually in parallel, with Olympic's keel laid down first on 16 December 1908 and Titanic's on 31 March 1909.[15] Both ships took about 26 months to build and followed much the same construction process. They were designed essentially as an enormous floating box girder, with the keel acting as a backbone and the frames of the hull forming the ribs. At the base of the ships, a double bottom 5 feet 3 inches (1.60 m) deep supported 300 frames, each between 24 inches (61 cm) and 36 inches (91 cm) apart and measuring up to about 66 feet (20 m) long. They terminated at the bridge deck (B Deck) and were covered with steel plates which formed the outer skin of the ships.[78]

The construction of Olympic and Titanic took place virtually in parallel, with Olympic's keel laid down first on 16 December 1908 and Titanic's on 31 March 1909.[15] Both ships took about 26 months to build and followed much the same construction process. They were designed essentially as an enormous floating box girder, with the keel acting as a backbone and the frames of the hull forming the ribs. At the base of the ships, a double bottom 5 feet 3 inches (1.60 m) deep supported 300 frames, each between 24 inches (61 cm) and 36 inches (91 cm) apart and measuring up to about 66 feet (20 m) long. They terminated at the bridge deck (B Deck) and were covered with steel plates which formed the outer skin of the ships.[78]The 2,000 hull plates were single pieces of rolled steel plate, mostly up to 6 feet (1.8 m) wide and 30 feet (9.1 m) long and weighing between 2.5 and 3 tons.[79] Their thickness varied from 1 inch (2.5 cm) to 1.5 inches (3.8 cm).[44] The plates were laid in a clinkered (overlapping) fashion from the keel to the bilge. Above that point they were laid in the "in and out" fashion, where strake plating was applied in bands (the "in strakes") with the gaps covered by the "out strakes", overlapping on the edges. Commercial oxy-fuel and electric arc welding methods, ubiquitous in fabrication today, were still in their infancy; like most other iron and steel structures of the era, the hull was held together with over three million iron and steel rivets,

which by themselves weighed over 1,200 tons. They were fitted using hydraulic machines or were hammered in by hand.[80] In the 1990s some material scientists concluded[81] that the steel plate used for the ship was subject to being especially brittle when cold, and that this brittleness exacerbated the impact damage and hastened the sinking. It is believed that, by the standards of the time, the steel plate's quality was good, not faulty, but that it was inferior to what would be used for shipbuilding purposes in later decades, owing to advances in the metallurgy of steelmaking.[81] As for the rivets, considerable emphasis has also been placed on their quality and strength.[82][83][84][85][86]

which by themselves weighed over 1,200 tons. They were fitted using hydraulic machines or were hammered in by hand.[80] In the 1990s some material scientists concluded[81] that the steel plate used for the ship was subject to being especially brittle when cold, and that this brittleness exacerbated the impact damage and hastened the sinking. It is believed that, by the standards of the time, the steel plate's quality was good, not faulty, but that it was inferior to what would be used for shipbuilding purposes in later decades, owing to advances in the metallurgy of steelmaking.[81] As for the rivets, considerable emphasis has also been placed on their quality and strength.[82][83][84][85][86]Among the last items to be fitted on Titanic before the ship's launch were her two side anchors and one centre anchor. The anchors themselves were a challenge to make, with the centre anchor being the largest ever forged by hand and weighing nearly 16 tons. Twenty Clydesdale draught horses were needed to haul the centre anchor by wagon from the Noah Hingley & Sons Ltd forge shop in Netherton, near Dudley, United Kingdom to the Dudley railway station two miles away. From there it was shipped by rail to Fleetwood in Lancashire before being loaded aboard a ship and sent to Belfast.[87]